Description

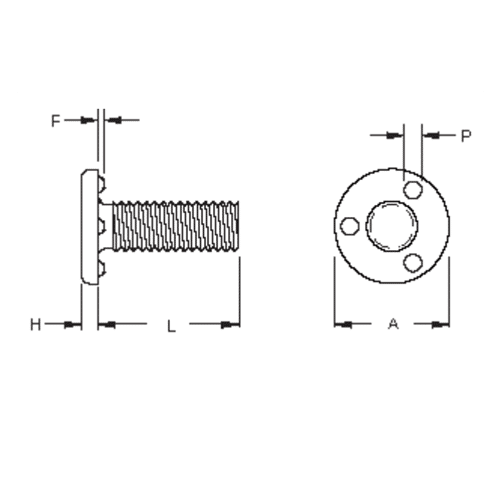

3 Projection Screw

Intended for through-hole applications, the HW weld screw, with its three projections located precisely under the head, permits flush mounting.

The projections are of the exact height, diameter and mass to assure the proper positioning and balance for optimum welds.

Through-hole use allows self-locating and eliminates the need for fixturing.

Arc Stud Welding vs CD Stud Welding

Capacitor Discharge (CD) Stud Welding is a semi-automatic arc welding process. Small diameter fasteners (1/4″ and under) are end welded to extremely thin gauge parent metal. The CD process operates on the principle of capacitor stored energy. The equipment system instantaneously discharges through a special weld “timing” tip. The entire weld cycle completes in several milliseconds. Welds can be made to thin sheet without pronounced distortion, burn-through or discoloration. CD welding can use dissimilar metals.

Process that allows a metal fastener to be welded to a parent metal through a fusion weld, also known as Arc Stud Welding. A “ferrule” captures and retains the weld’s heat. The process creates molten metal that cools the weld site. The weld produced is stronger than the stud itself. Arc stud welding can use dissimilar metals such as mild and stainless steel, as well as aluminum.

Not What You’re Looking For?

View all of our excess inventory here. Additionally, see our full selection of studs here, as well as our full line of equipment options here.

Have Questions?

For more information on this product, call our office at 800-252-1919 or email us at Info@studweldprod.com and we will get back to you shortly!

Follow Us on Social Media!

Your #1 Stud! on Instagram and Facebook. Also, check out our YouTube channel here.

Reviews

There are no reviews yet.