Description

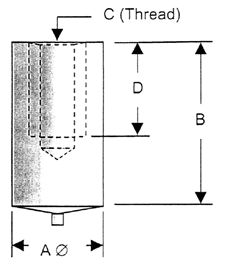

Tapped Pad Non-Flanged CD Studs

Capacitor Discharge (CD) Stud Welding is a semi-automatic arc welding process. However, with CD welding small diameter fasteners (1/4″ and under) are end welded to extremely thin gauge parent metal. The CD process operates on the principle of capacitor stored energy which is instantaneously discharged by the equipment system through a special weld “timing” tip. Since the entire weld cycle is completed in several milliseconds, welds can be made to thin sheet without pronounced distortion, burn-through or discoloration. CD welding permits stud welding of dissimilar metals.

Tapped Pad Non-Flanged CD Studs are affordable, high quality metal fasteners perfect for CD welding needs. These Non-Flanged CD Studs come in various dimensions, making these one of the most versatile studs on the market. Guaranteed to work flawlessly with any capacitive discharge welder we offer!

To view our full selection of capacitor discharge studs and arc studs, click here. Click here to view our selection of capacitive discharge stud welders.

Taps: Standard tap is UNC-2B, other taps are available.

Material: Low Carbon Steel, Stainless Steel and Aluminum

Mechanical Properties: Tensile (60,000) psi (min.) Yeild (50,000) psi (min.) Elongation 20% (in 2 inches)

Plating: Plating is not standard. Copper, nickel, and zine available upon customer request

| A | B (MIN) | C (MAX) | D (MIN) |

|---|---|---|---|

| 3/16 | 3/8 | 6/32 | 1/4 |

| 1/4 | 3/8 | 8-32 | 1/4 |

| 5/16 | 3/8 | 10-32 | 14 |

| 3/8 | 3/8 | 1/4-20 | 1/4 |

*Maximum standard tap depth equals 1-1/2 times tap diameter.

Reviews

There are no reviews yet.