Description

Tapped Studs are used in all types of applications. They can be welded to a flat surface, or to the inside or outside of an angle.

Arc stud welding is a process by which a metal fastener is welded to a parent metal through a fusion weld. Using a “ferrule” to capture and retain the weld’s heat, the molten metal created by the process cools and the weld site and produces a weld that is stronger than the stud itself. Drawn arc stud welding can weld dissimilar metals such as mild and stainless steel, as well as aluminum.

Our Tapped studs are composed of low-carbon steel or stainless steel. All purchases of Tapped studs come with the necessary ferrules required for welding, so you do not have to worry about making sure you have the necessary parts!

To view our full selection of capacitor discharge studs and arc studs, click here. Click here to view our selection of arc stud welders.

Have Questions?

For more information on this product, email us at Info@studweldprod.com or call our office at 800-252-1919 and we will get back to you shortly!

How to Order:

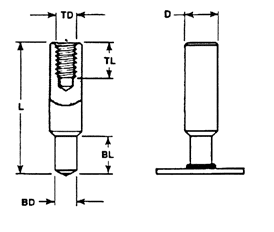

Specify base diameter, finished length before weld (BW) length, tap size, tap depth and type of material.

Ex: 5/8 x 1-1/4” (BW) Tapped Stud (TS) with a 3/8-16 x 7/16 tap, mild steel

When ordering Stainless Steel, SS will be added to the part number.

How to determine Before Weld (BW) Length

First establish the standing length of the stud after weld (AW).

Based on the diameter of the stud, include the following additional length before weld (BW).

Diameters up through 9/16″ add 1/8″ (will be 1/8” shorter AFTER weld)

Diameters from 5/8″ through 7/8″ add 3/16″ (will be 3/16” shorter AFTER weld)

Diameters 1″ through 1 1/4″ add 1/4″ (will be 1/4” shorter AFTER weld)

| Low Carbon Mechanical Property Requirements | Stainless Steel | ||

|---|---|---|---|

| Tensile Strength | 61,000 psi min. | Material: Stainless Steel AISI grade - 302/304/316. Other grades available upon request. Mechanical Properties: Values for various grades available upon request. |

|

| Yield Strength | 49,000 psi min. | ||

| Elongation (% in 2 in.) | 17% min. | ||

| Elongation (% in 5x dia.) | 14% min. | ||

| Reduction of Area | 50% min. |

Reviews

There are no reviews yet.